Wood Finishing:

I firmly believe that one of the most important parts of any project involving wood is the finishing process.This can turn a decent project into a disaster if not done properly and this is compounded further when the wood is of the calibre that I used in this project.

I used two different finishes for this case. The maple received a simple tung oil and polyurethane mix (store bought) which was a wipe on, wipe off, sand, and repeat procedure.

The ebony was slightly more complicated because of the different properties of the wood. For this I used a thinned straight polyurethane, but did the same procedure as the tung oil.

Since the ebony is so hard, any scratch would show. Because of this, I had to be extra vigilant during the sanding process. This meant sanding from 220 grit all the way up to 800 before and between coats of finish. The result is a decently high lustre finish that shows off the beautiful qualities of both woods.

Aluminium

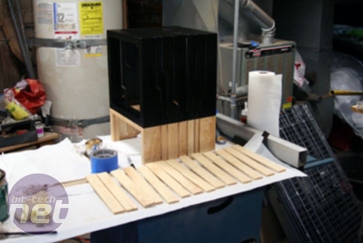

For the skeleton of the case, aluminium was the natural choice. Luckily for me I had AC Ryan as a sponsor and I used around four sheets each of their black 1mm and 2mm anodised aluminium, a product I quickly grew fond of. To cut this material, (along with other sheets of plain 6061 aluminium) I used my table saw with my trusty non-ferrous metal blade.Main Frame

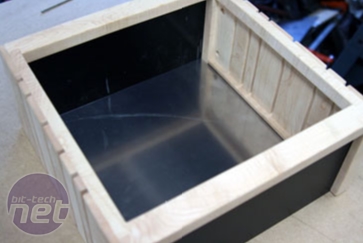

The main aluminium frame was easily the hardest piece to design of the entire case as it had to contain all the systems along with support for the wood pieces while enabling me to take them off and apart if necessary. I came up with a design where the aluminium frame is free standing and the wood sections slide over and stop where they are supposed to (this will make more sense later).The first step was to make the “floors” for each wood section. The maple section needed a floor which would be bigger than the rest and would be the most structurally significant. For this I used 1/8 inch 6061 aluminium cut to fit snuggly within the maple.

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.